Providing solutions to difficult projects

Heavy civil, mechanical, environmental, and marine construction experts

Who We Are

We are

Syblon Reid

Founded in 1955, we established the belief that our future is secured through past performance.

Services

Our extensive

Our extensive

experience spans

numerous services;

If it involves water, we're your contractor of choice.

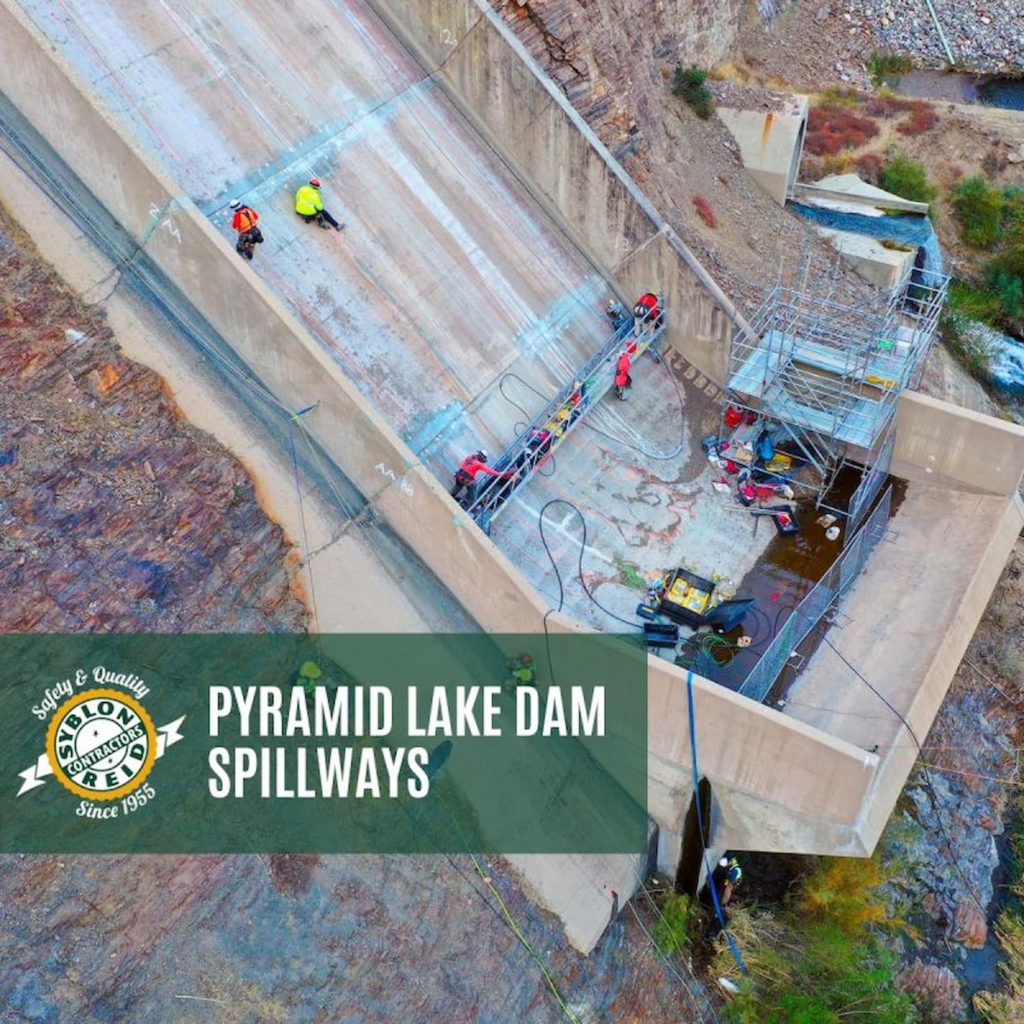

Featured Projects

Our featured

projects

Explore all projects

We work with a wide

variety of markets

Learn more

- Environmental

- Industrial

- Marine

- Federal

- Governmental

News

Latest news

View all news